Products & Services

List of products

Catalogs

Mixers

Small machines

Water treatment

Petrochemistry

Food & beverage

Medicines

Bio & regenerative medical techniques

Paints

Paper manufacturing

For experiments

Super-mix Series

Classifier

Bioreactors

Realization of Industrialization / Commercial Production / Scalability

Microbial culture

HSF ReactorAnimal cell culture

MRF ReactorAnimal cell culture

MRF-RB ReactorAnimal cell culture

VMF ReactorAnimal cell culture

VerSus ReactorRegenerative medicine

VMF-WSUB Reactor/TCSSingle-use BioReactor

iPS cell culture

HiD4×4Fittings/Options

Solutions

Development of exclusive mixers・

and impellers by purpose of useContracted numerical calculation

Evaluation of contracted cell culture

Classification performance evaluation

Environmental testing equipment

Bioreactors

HSF Reactor

MRF Reactor

MRF-RB Reactor

VMF Reactor

VerSus Reactor

VMF-WSUB

Reactor/TCSSingleUse

BioReactorHiD4x4

Fittings/Options

MRF Reactor

Rotating type mixer for cell culture equipped with an MR210Bio impeller as a standard

Development, Customization, and Single-use support of Exclusive Reactor in Accordance with Requirements Specifications

With the help of the dedicated controller “S-BOX × 10α II”, changes in various parameters including PI control can be easily performed.

Mixing Impeller Super-mix MR210Bio Used Exclusively for Cell Culture

・Exhibits high mixing performance at low shear

・Simple shape with excellent washing ability

・Completely compatible with fluid surface fluctuation

・The same culture results as in the laboratory can be reproduced during scale-up too.

An environment that is best suited for cell culture is created through excellent mixing performance.

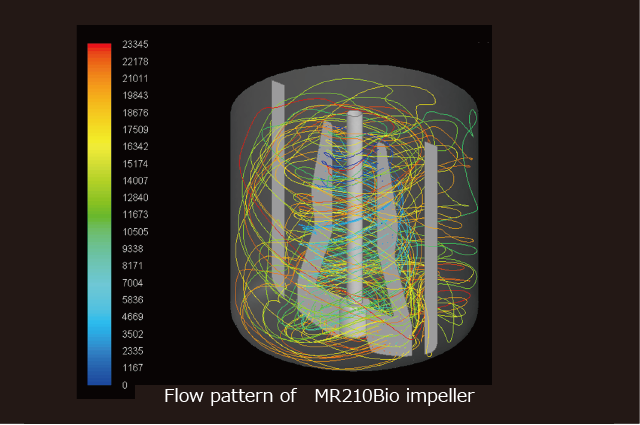

■Flow condition inside culture tank

CFD Simulation Analysis Result

The “MR210Bio” impeller developed exclusively for cell culture produces a high circulating flow that runs from the low-pressure area at the bottom of the blades, where the mixing homogeneity inside the tank is high, toward the top of the tank. As a result of this feature, a high homogeneity and fluidity are obtained even at low power and low rotation, and at the same time, the basic flow pattern does not change even when the fluid surface fluctuates. It is known as an impeller used exclusively for cell culture that adapts to unsteadiness, which was not seen in the past in any impeller, and is suitable for operation under conditions where the fluid surface fluctuates as a result of fed-batch culture. A high circulation performance can be seen from the CFD simulation analysis results.

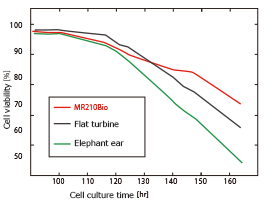

■Culture example

Comparison of the cell viability in the later stage of the culture by CHO cells

Here we show the cell viability in the later stage of the culture under the batch cell culture condition for the turbine type (flat turbine) and wide paddle type (elephant ear) impellers used in the conventional rotating type BioReactor. It can be confirmed that the MRF reactor maintains a higher cell viability than the other conventional impellers in the later stage of the culture. A characteristic of the MR210Bio that has a low shearing action and high mixing homogeneity performance is the realization of scale-up to a large-size reactor through the combined use of numerical fluid calculation.

| Item | Specifications | |||

|---|---|---|---|---|

| Name | MRF Reactor | |||

| Model | MRF-3 | MRF-8 (10 [%] Dish bottom head) | MRF-10 | |

| Temp. control device | Band heater (PID control) with over-temperature protection function (Max. 80 [℃]) | |||

| Power transmission | Magnet drive (non-sealing type) | |||

| Gas supply type | Shirasu porous glass (SPG) membrane type / sintered metal type (selectable) | |||

| Performance*1 | Temp. control range | Room temperature + 5 - 20 [℃] (normally set to 37 [℃]) | ||

| Temp. accuracy | ±0.3 [℃](37 [℃]) | |||

| Rotational speed range | 5 - 200 [min-1] | |||

| Function | Temp. setting | Touch panel input, data output DC1 - 5 [V] | ||

| Speed setting | Touch panel input, data output DC0 - 10 [V] | |||

| Configuration | Power of band heater | Max. 160 [W] | Max. 480 [W] | Max. 480 [W] |

| Power of motor | Max. output 100 [W] | |||

| Mixing impeller | Super-Mix MR210Bio impeller | |||

| Culture tank | Dimensions | I.D. 140 x Depth 203 [mm] | I.D. 200 x Depth 330 [mm] | I.D. 200 x Depth 360 [mm] |

| Culture operation volume | 2.4 [L] | 6 [L] (10 [%] Dish bottom head) | 7 [L] | |

| Usage condition | 10 - 35 [℃] | |||

| Outer dimensions | W360×D485×H905 [mm] | |||

| Weight | Approx. 30 [kg] | Approx. 34 [kg] | Approx. 34 [kg] | |

| Power supply | AC100 [V], 50 /60 [Hz] | |||

| *1 The performance is the value under room temperature 20 [℃], power supply AC100 [V], 50 [Hz] and no load condition. | ||||

| Item | Specifications | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Name | Culture controller | |||||||||||

| Model | S-BOX×10αII | |||||||||||

| Control | pH, DO (Dissolved oxygen), FL (O₂ flow rate), Pump | |||||||||||

| Display range/accuracy | pH (Hydrogen ion concentration) | 0.00 - 14.00 [-] | Display accuracy: ±0.5 [%] F.S. | |||||||||

| DO (Dissolved oxygen) | 0.00 - 20.00 [mg/L] | |||||||||||

| FL (O2flow rate) | 0.00 - 20.00 [mL/min] | |||||||||||

| Setting range | pH (Hydrogen ion concentration) | 0.00 - 14.00 [-] | ||||||||||

| DO (Dissolved oxygen) | 0.00 - 10.00 [mg/L] | |||||||||||

| FL (O2flow rate) | 0.00 - 20.00 [mL/min] | |||||||||||

| Control type | pH (Hydrogen ion concentration) | ON/OFF control | ||||||||||

| DO (Dissolved oxygen) | O2addition/subtraction step control | |||||||||||

| O2and N2ON/OFF control | ||||||||||||

| O2PI control (slope set method: TIME, %) | ||||||||||||

| FL (O2flow rate) | PI control (slope set method: TIME, %) | |||||||||||

| Data output | pH (Hydrogen ion concentration) | With data logger DC0 - 5 [V] |

Accuracy: ±0.5 [%] F.S. | |||||||||

| DO (Dissolved oxygen) | ||||||||||||

| FL (O2flow rate) | ||||||||||||

| Rotational speed | DC0 - 10 [V] | |||||||||||

| Temperature sensor | DC1 - 5 [V] | |||||||||||

| MTA of outer surface | SUS304 (no coating), indoor type, non-waterproof, non-explosion proof specification | |||||||||||

| Installation | Indoor tabletop type | |||||||||||

| Outer dimensions/weight | W350×D400×H530 [mm] ・ Approx. 15 [kg] | |||||||||||

| Usage conditions | Temperature | 5 - 45 [℃] | Humidity | 20 - 85 [%] RH (No condensation) | ||||||||

| Sensors | Polarographic DO sensor/pH sensor manufactured by Mettler Toledo company | |||||||||||

| (Option: Optical DO sensor manufactured by Automatic System Research Co., Ltd.) | ||||||||||||

| Utilities | Power supply | AC100 [V], 50/60 [Hz], electrical outlet 2 gang (for main control unit and recorder) | ||||||||||

| N2 | Flow rate 50 [mL/min] or lower, supply pressure 0.2 [MPa], Connection port φ6 one touch tube fitting |

|||||||||||

| O2 | Flow rate 20 [mL/min] or lower, supply pressure 0.2 [MPa], connection port φ6 one touch tube fitting |

|||||||||||

| CO2 | Flow rate 50 [mL/min] or lower, supply pressure 0.2 [MPa], connection port φ6 one touch tube fitting |

|||||||||||

| AIR | Flow rate 150 [mL/min] or lower, supply pressure 0.2 [MPa], connection port φ6 one touch tube fitting |

|||||||||||

| *All of N₂, O₂, CO₂, and AIR must be dry and clean gases that do not contain corrosive components, dust, and oil mist. | ||||||||||||

| Item | Specifications | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Name | Culture controller | |||||||||||

| Model | S-BOX×10 Simple | |||||||||||

| Control | pH, DO (Dissolved oxygen) | |||||||||||

| Display range/accuracy | pH (Hydrogen ion concentration) | 0.00 - 14.00 [-] | Display accuracy: ±0.5 [%] F.S. | |||||||||

| DO (Dissolved oxygen) | 0.00 - 20.00 [mg/L] | |||||||||||

| Setting range | pH (Hydrogen ion concentration) | 0.00 - 14.00 [-] | ||||||||||

| DO (Dissolved oxygen) | 0.00 - 10.00 [mg/L] | |||||||||||

| Control type | pH (Hydrogen ion concentration) | ON/OFF control | ||||||||||

| DO (Dissolved oxygen) | ||||||||||||

| Data output | pH (Hydrogen ion concentration) | With data logger DC0 - 5 [V] |

Accuracy: ±0.5 [%] F.S. | |||||||||

| DO (Dissolved oxygen) | ||||||||||||

| Rotational speed | DC0 - 10 [V] | |||||||||||

| Temperature sensor | DC1 - 5 [V] | |||||||||||

| MTA of outer surface | SUS304 (no coating), indoor type, non-waterproof, non-explosion proof specification | |||||||||||

| Installation | Indoor tabletop type | |||||||||||

| Outer dimensions/weight | W260×D300×H350 [mm] ・ Approx. 12 [kg] | |||||||||||

| Usage conditions | Temperature | 5 - 45 [℃] | Humidity | 20 - 85 [%] RH (No condensation) | ||||||||

| Sensors | Optical DO sensor manufactured by Automatic System Research Co., Ltd. + pH sensor manufactured by Mettler Toledo company |

|||||||||||

| Utilities | Power supply | AC100[V], 50/60 [Hz], electrical outlet 2 gang (for main control unit and recorder) | ||||||||||

| O2 | Flow rate 20 [mL/min] or lower, supply pressure 0.2 [MPa], connection port φ6 one touch tube fitting |

|||||||||||

| CO2 | Flow rate 50 [mL/min] or lower, supply pressure 0.2 [MPa], connection port φ6 one touch tube fitting |

|||||||||||

| AIR | Flow rate 150 [mL/min] or lower, supply pressure 0.2 [MPa], connection port φ6 one touch tube fitting |

|||||||||||

| *All of O₂, CO₂, and AIR must be dry and clean gases that do not contain corrosive components, dust, and oil mist. | ||||||||||||