Products & Services

List of products

Catalogs

Mixers

Small machines

Water treatment

Petrochemistry

Food & beverage

Medicines

Bio & regenerative medical techniques

Paints

Paper manufacturing

For experiments

Super-mix Series

Classifier

Bioreactors

Realization of Industrialization / Commercial Production / Scalability

Microbial culture

HSF ReactorAnimal cell culture

MRF ReactorAnimal cell culture

MRF-RB ReactorAnimal cell culture

VMF ReactorAnimal cell culture

VerSus ReactorRegenerative medicine

VMF-WSUB Reactor/TCSSingle-use BioReactor

iPS cell culture

HiD4×4Fittings/Options

Solutions

Development of exclusive mixers・

and impellers by purpose of useContracted numerical calculation

Evaluation of contracted cell culture

Classification performance evaluation

Environmental testing equipment

Bioreactors

HSF Reactor

MRF Reactor

MRF-RB Reactor

VMF Reactor

VerSus Reactor

VMF-WSUB

Reactor/TCSSingleUse

BioReactorHiD4x4

Fittings/Options

HSF Reactor

High-performance BioReactor with the high-efficiency turbine HS100 / high-discharge axial flow impeller HR100 as a standard

High-Efficiency Turbine, In-Tank Coil Heat Transmission Specs, Dedicated for Actual Machine Scale-up

An optional cooling chiller can be attached, and when using a heat transfer coil type similar to the actual machine, you can achieve conditions that are closer to the actual machine. As a specialty manufacturer of mixing device with the only dedicated mixing technology laboratory in Japan, we can apply final optimizations for actual machine and customize the device according to the physical properties of its contents.

High performance turbine impeller and axial flow impeller are standard specifications

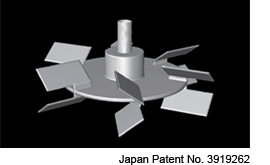

■HS100 turbine

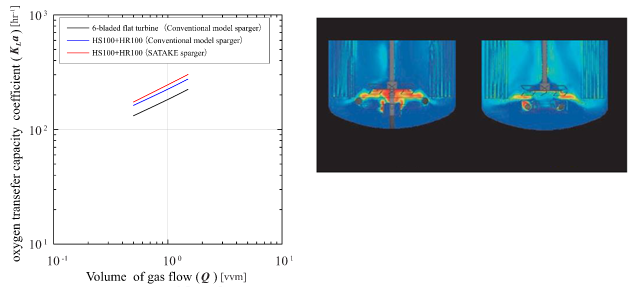

The HS100 turbine achieves an extremely low power number (Power number ratio to 6FT: approx. 65% reduction). Liquid fluidizing action is improved compared to conventional turbines, along with high-performance gas absorption (KLa). Impeller lift at low power creates more focused flow, utilizing pressure gradients and fluctuations of the discharge field to produce powerful shearing and destructive action. When paired with the high-discharge type HR100 Impeller, this impeller achieves overall incredibly highly efficient in-tank liquid fluidizing action, shearing, and destructive action (gas dispersion).

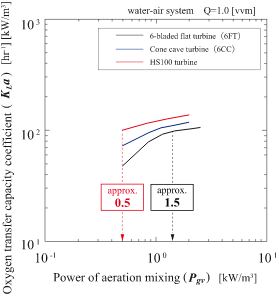

Comparison of gas

absorption performance (kLa)

6 flat

turbine

HS100

turbine

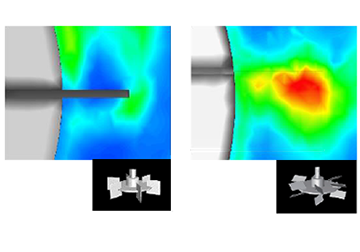

CFD flow analysis result near the blade

(blade cross section)

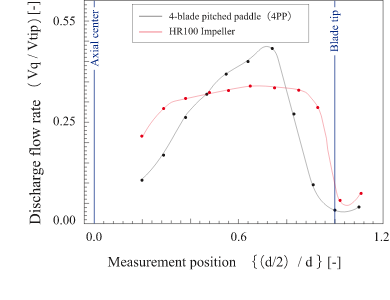

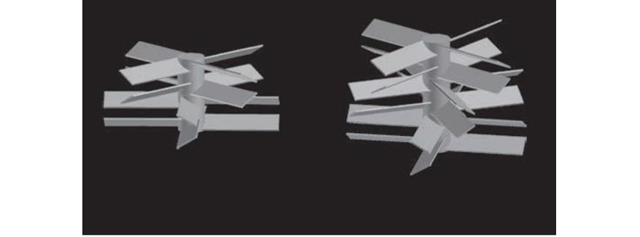

■HR100 Impeller

In addition to considerations regarding the plane shape of the impeller, the angle of attack, and the camber ratio, the HR100 Impeller features a multistage curved structure, and suppressing separation on the rear surface of the impeller results in an energy-saving, low-shear type axial flow impeller that boasts high discharge performance at low power. This product excels at liquid-liquid mixing, solid-liquid dispersion, uniform suspension of particles that are fragile and lightweight, emulsified micro-capsules (latex, etc.), and is effective in combinations that utilize superior axial fluidizing action in multi-stage mixing.

Flow pattern of the HR100 Impeller

Discharge performance by LDV

(compared with conventional 4PP model)

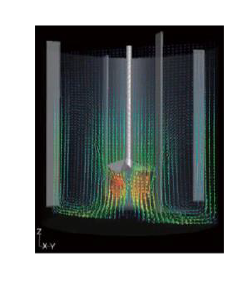

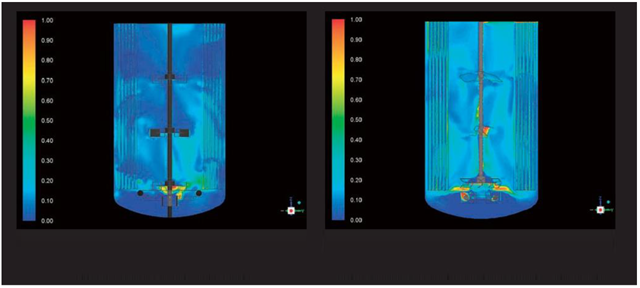

Example of 200 kL Actual Machine CFD

Simulation Analysis

Conventional model: 6-bladed flat turbine triple stage

Satake model: HR100 double stage + HS100 single stage

Gas dispersion comparison results via multiphase flow model (Euler-Euler)

of 200 kL culture tank in CFD simulation

When using the conventional 6-bladed flat turbine in multi-stage within a culture tank, the flow is divided creating conditions that are not favorable to uniform dispersion inside the culture tank. With this in mind, a new, high-performance BioReactor is created by utilizing the flow action in the axial direction of high-discharge axial flow impeller HR100 on the top of the tank in combination with high-dispersion turbine HS100 on the bottom of the tank for gas dispersion action, resulting in uniform dispersion inside the culture tank and high-performance gas absorption. HSF reactors are suitable for lab-scale consideration from 3 to 10 L, and can also be scaled up to production machines (large capacity) at the same requirements.

Super-mix® HS124ND, HS134ND Turbine

HS124ND

Japan Patent No. 6159577

HS134ND

Japan Patent No. 6159577

Ultra high-efficiency turbines HS124ND/HS134ND boast gas absorption performance that exceeds even that of the high-efficiency turbine HS100. The upper and lower impellers create effective discharge action, achieving a high level of gas absorption performance and required OTR. Technology that delivers the world's highest gas absorption performance and required OTR is available at laboratory scale in 200 - 300 kL-class actual machines.

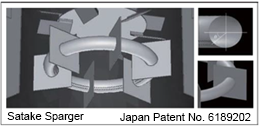

SATAKE Sparger

The Satake Sparger is designed with gas discharge direction in mind so that aerated gas passes near the impeller, which is where the shearing field is located. Also, a stationary impeller is attached to the ring, and increasing the velocity gradient of the flow improves shearing and destructive action. Furthermore, the stationary impeller strengthens the discharge action. These actions efficiently disperse gases.

Conventional Sparger

SATAKE Sparger

200kL-F culture tank simulation results

Gas-liquid multiphase flow gas fraction analysis

The Satake Sparger is effective when paired with the HS100. The synergistic effect with the optimized mixing impeller significantly improves the gas dispersion action, increasing gas absorption performance. (According to our test results)

| Item | Specifications | ||||

| Name | HSF Reactor | ||||

| Model | HSF-3 | HSF-10 | |||

| Temp. control device | Band heater (PID control) with over-temperature protection function (Max. 80 [℃]) + (option : In-vessel coil heat exchanger) |

||||

| Power transmission | Magnet drive (non-sealing type) | ||||

| Gas supply type | Ring sparger (option : SATAKE sparger) | ||||

| Performance*1 | Temp. control range | Room temperature + 5 - 20 [℃] (normally set to 37 [℃]) | |||

| Temp. accuracy | ±0.3 [℃](37 [℃]) | ||||

| Rotational speed range | 5 - 1500 [min-1] | ||||

| Function | Temp. setting | Touch panel input, data output DC1 - 5 [V] | |||

| Speed setting | Touch panel input, data output DC0 - 10 [V] | ||||

| Configuration | Power of band heater | Max. 160 [W] | Max. 480 [W] | ||

| Power of motor | Max. output 100 [W] | Max. output 400 [W] | |||

| Mixing impellers | Super-Mix HS100 turbine + HR100 impeller | ||||

| Culture tank | Dimensions | I.D. 140 x Depth 203 [mm] | I.D. 200 x Depth 360 [mm] | ||

| Culture operation volume | 2.4 [L] | 6 [L] | |||

| Usage condition | 10 - 35 [℃] | ||||

| Outer dimensions | W360×D485×H905 [mm] | W360×D485×H980 [mm] | |||

| Weight | Approx. 30 [kg] | Approx. 34 [kg] | |||

| Power supply | AC100 [V], 50/60 [Hz] | ||||

| *1 The performance is the value under room temperature 20 [℃], power supply AC100 [V], 50 [Hz] and no load condition. | |||||

| Item | Specifications | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Name | Culture controller | |||||||||||

| Model | S-BOX × 10 MC | |||||||||||

| Control | pH, DO (Dissolved oxygen), FL (O₂ flow rate), FL (Air flow rate), Pump | |||||||||||

| Display range/ accuracy | pH (Hydrogen ion concentration) | 0.00 - 14.00 [-] | Display accuracy: ±0.5 [%] F.S. | |||||||||

| DO (Dissolved oxygen) | 0.00 - 20.00 [mg/L] | |||||||||||

| FL(O2flow rate) | 0.4 - 10.0 [L/min] | |||||||||||

| FL(AIR flow rate) | 0.4 - 20.0 [L/min] | |||||||||||

| Setting range | pH (Hydrogen ion concentration) | 0.00 - 14.00 [-] | ||||||||||

| DO (Dissolved oxygen) | 0.00 - 10.00 [mg/L] | |||||||||||

| FL(O2flow rate) | 0.4 - 10.0 [L/min] | |||||||||||

| FL(AIR flow rate) | 0.4 - 20.0 [L/min] | |||||||||||

| Control type | pH (Hydrogen ion concentration) | ON/OFF control | ||||||||||

| DO (Dissolved oxygen) | ||||||||||||

| AF (antifoam) | ||||||||||||

| Data output | pH (Hydrogen ion concentration) | With data logger DC0 - 5 [V] |

Accuracy: ±0.5 [%] F.S. | |||||||||

| DO (Dissolved oxygen) | ||||||||||||

| FL(O2flow rate) | ||||||||||||

| FL(AIR flow rate) | ||||||||||||

| AF (antifoam) | ||||||||||||

| Rotational speed | DC0 - 10 [V] | |||||||||||

| Temperature sensor | DC1 - 5 [V] | |||||||||||

| MTA of outer surface | SUS304 (no coating), indoor type, non-waterproof, non-explosion proof specification | |||||||||||

| Installation | Indoor tabletop type | |||||||||||

| Outer dimensions/weight | W260×D320×H400 [mm] ・ Approx. 15 [kg] | |||||||||||

| Usage conditions | Temperature | 5 - 45 [℃] | Humidity | 20 - 85 [%] RH (No condensation) | ||||||||

| Sensors | Polarographic DO sensor/pH sensor manufactured by Mettler Toledo company | |||||||||||

| (Option: Optical DO sensor manufactured by Automatic System Research Co., Ltd.) | ||||||||||||

| Utilities | Power supply | AC100 [V], 50/60 [Hz], electrical outlet 2 gang (for main control unit and recorder) | ||||||||||

| O2 | Flow rate 10 [L/min] or lower, supply pressure 0.2 [MPa], connection port φ6 one touch tube fitting |

|||||||||||

| CO2 | Flow rate 50 [mL/min] or lower, supply pressure 0.2 [MPa], connection port φ6 one touch tube fitting |

|||||||||||

| AIR (for pH) | Flow rate 5 [L/min] or lower, supply pressure 0.2 [MPa], connection port φ6 one touch tube fitting |

|||||||||||

| AIR (for DO) | Flow rate 20 [L/min] or lower (controlled with mass flow controller), supply pressure 0.2 [MPa], connection port φ6 one touch tube fitting | |||||||||||

| *All of O₂, CO₂, and AIR must be dry and clean gases that do not contain corrosive components, dust, and oil mist. | ||||||||||||

| Item | Specifications | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Name | Culture controller | |||||||||||

| Model | S-BOX×10 Simple | |||||||||||

| Control | pH, DO (Dissolved oxygen) | |||||||||||

| Display range/ accuracy | pH (Hydrogen ion concentration) | 0.00 - 14.00 [-] | Display accuracy: ±0.5 [%] F.S. | |||||||||

| DO (Dissolved oxygen) | 0.00 - 20.00 [mg/L] | |||||||||||

| Setting range | pH (Hydrogen ion concentration) | 0.00 - 14.00 [-] | ||||||||||

| DO (Dissolved oxygen) | 0.00 - 10.00 [mg/L] | |||||||||||

| Control type | pH (Hydrogen ion concentration) | ON/OFF control | ||||||||||

| DO (Dissolved oxygen) | ||||||||||||

| Data output | pH (Hydrogen ion concentration) | With data logger DC0 - 5 [V] |

Accuracy: ±0.5 [%] F.S. | |||||||||

| DO (Dissolved oxygen) | ||||||||||||

| Rotational speed | DC0 - 10 [V] | |||||||||||

| Temperature sensor | DC1 - 5 [V] | |||||||||||

| MTA of outer surface | SUS304 (no coating), indoor type, non-drip proof, non-explosion proof specification | |||||||||||

| Installation | Indoor tabletop type | |||||||||||

| Outer dimensions/weight | W260×D300×H350 [mm] ・ Approx. 12 [kg] | |||||||||||

| Usage conditions | Temperature | 5 - 45 [℃] | Humidity | 20 - 85 [%] RH (No condensation) | ||||||||

| Sensors | Optical DO sensor manufactured by Automatic System Research Co., Ltd. | |||||||||||

| + pH sensor manufactured by Mettler Toledo company | ||||||||||||

| Utilities | Power supply | AC100 [V], 50/60 [Hz], electrical outlet 2 gang (for main control unit and recorder) | ||||||||||

| O2 | Flow rate 20 [mL/min] or lower, supply pressure 0.2 [MPa], connection port φ6 one touch tube fitting |

|||||||||||

| CO2 | Flow rate 50 [mL/min] or lower, supply pressure 0.2 [MPa], connection port φ6 one touch tube fitting |

|||||||||||

| AIR | Flow rate 150 [mL/min] or lower, supply pressure 0.2 [MPa], connection port φ6 one touch tube fitting |

|||||||||||

| *All of O₂, CO₂, and AIR must be dry and clean gases that do not contain corrosive components, dust, and oil mist. | ||||||||||||