Products & Services

List of products

Catalogs

Mixers

Small machines

Water treatment

Petrochemistry

Food & beverage

Medicines

Bio & regenerative medical techniques

Paints

Paper manufacturing

For experiments

Super-mix Series

Classifier

Bioreactors

Realization of Industrialization / Commercial Production / Scalability

Microbial culture

HSF ReactorAnimal cell culture

MRF ReactorAnimal cell culture

MRF-RB ReactorAnimal cell culture

VMF ReactorAnimal cell culture

VerSus ReactorRegenerative medicine

VMF-WSUB Reactor/TCSSingle-use BioReactor

iPS cell culture

HiD4×4Fittings/Options

Solutions

Development of exclusive mixers・

and impellers by purpose of useContracted numerical calculation

Evaluation of contracted cell culture

Classification performance evaluation

Environmental testing equipment

Bioreactors

HSF Reactor

MRF Reactor

MRF-RB Reactor

VMF Reactor

VerSus Reactor

VMF-WSUB

Reactor/TCSSingleUse

BioReactorHiD4x4

Fittings/Options

MRF-RB Reactor

Low-shear, high-dispersion mixing system combined with the RB Mixing System

Development, Customization, and Single-use support of Exclusive Reactor in Accordance with Requirements Specifications

Low-power, low shear action continuous BioReactor equipped with high-efficiency mixing system

■RB Mixing system

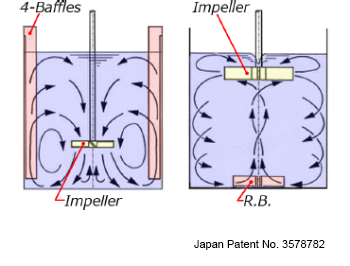

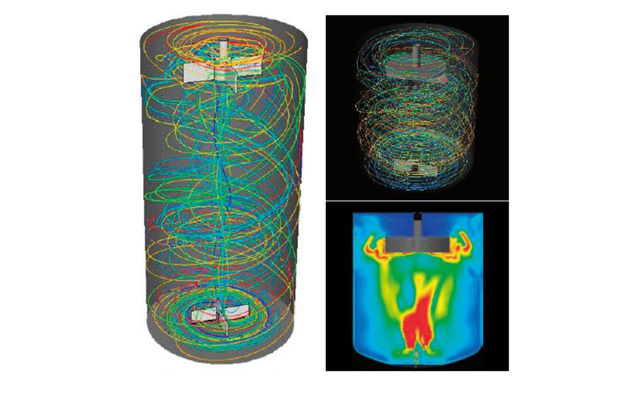

In general, mixing is accomplished by using impellers to fluidize liquid. The role of impellers in the RB mixing system is not active mixing. The hint lies in natural flow and rectification action, and tornadoes, which are powerful enough to lift up houses. We wondered what the rectification action and tornado forces would create inside the mixing tank. The RB mixing system consists of an impeller, which generates a swirling flow inside the mixing tank, and radial blades that efficiently exchanges the swirling flow (boundary layer effect) toward the center at the bottom of the mixing tank with a tornado-shaped upward flow, forming a system that creates flow patterns that were unthinkable in conventional mixing. The ”RB” in the name comes from its Radial Blade component. Because the swirling flow is the main flow, the relative velocity difference near the blade is diminished, creating an extremely low shear action and superb uniform cell dispersion inside the culture tank, resulting in efficient mixing for biochemicals, pharmaceuticals, energy generation (water treatment), and other applications.

Mixing method comparison table

※Vtip:Blade tip peripheral speed

| Mixing method | Maximum upward flow velocity coefficient % (vs. Vtip* ratio) |

Impeller/liquid relative velocity difference coefficient (shear velocity ratio) |

Maximum possible mixing vertical ratio (depth H/tank diameter D) |

|---|---|---|---|

| SUPER-MIX RB mixing system |

87 | 0.4 | 5 or more possible |

| Mixing with four baffle plates | 30 | 0.8 | Up to about 2 |

| Mixing without baffle plates | 15 | 0.4 | Up to about 1.5 |

Conventional

mixing

RB Mixing System

CFD simulation analysis results

High depth,

high circulation formation

Flow action (upper)

/shear stress (lower)

| Item | Specifications | ||||

|---|---|---|---|---|---|

| Name | MRF-RB Reactor | ||||

| Model | MRF-RB-3 | MRF-RB-10 | |||

| Temp. control device | Band heater (PID control) with over-temperature protection function (Max. 80 [℃]) | ||||

| Power transmission | Magnet drive (non-sealing type) | ||||

| Gas supply type | Shirasu porous glass (SPG) membrane type / sintered metal type (selectable) | ||||

| Performance*1 | Temp. control range | Room temperature + 5 - 20 [℃] (normally set to 37 [℃]) | |||

| Temp. accuracy | ±0.3 [℃](37 [℃]) | ||||

| Rotational speed range | 5 - 200 [min-1] | ||||

| Function | Temp. setting | Touch panel input, data output DC1 - 5 [V] | |||

| Speed setting | Touch panel input, data output DC0 - 10 [V] | ||||

| Configuration | Power of band heater | Max. 160 [W] | Max. 480 [W] | ||

| Power of motor | Max. output 100 [W] | ||||

| Mixing impeller | RB Mixing System | ||||

| Culture tank | Dimensions | I.D. 140 x Depth 203 [mm] | I.D. 200 x Depth 360 [mm] | ||

| Culture operation volume | 2.4 [L] | 7 [L] | |||

| Usage condition | 10 - 35 [℃] | ||||

| Outer dimensions | W360×D485×H905 [mm] | ||||

| Weight | Approx. 30 [kg] | Approx. 34 [kg] | |||

| Power supply | AC100 [V], 50/60 [Hz] | ||||

| *1 The performance is the value under room temperature 20 [℃], power supply AC100 [V], 50 [Hz] and no load condition. | |||||

| Item | Specifications | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Name | Culture controller | |||||||||||

| Model | S-BOX×10αII | |||||||||||

| Control | pH, DO (Dissolved oxygen), FL (O₂ flow rate), Pump | |||||||||||

| Display range/accuracy | pH (Hydrogen ion concentration) | 0.00 - 14.00 [-] | Display accuracy: ±0.5 [%] F.S. | |||||||||

| DO (Dissolved oxygen) | 0.00 - 20.00 [mg/L] | |||||||||||

| FL (O2flow rate) | 0.00 - 20.00 [mL/min] | |||||||||||

| Setting range | pH (Hydrogen ion concentration) | 0.00 - 14.00 [-] | ||||||||||

| DO (Dissolved oxygen) | 0.00 - 10.00 [mg/L] | |||||||||||

| FL (O2flow rate) | 0.00 - 20.00 [mL/min] | |||||||||||

| Control type | pH (Hydrogen ion concentration) | ON/OFF control | ||||||||||

| DO (Dissolved oxygen) | O2addition/subtraction step control | |||||||||||

| O2and N2ON/OFF control | ||||||||||||

| O2PI control (slope set method: TIME, %) | ||||||||||||

| FL (O2flow rate) | PI control (slope set method: TIME, %) | |||||||||||

| Data output | pH (Hydrogen ion concentration) | With data logger DC0 - 5 [V] |

Accuracy: ±0.5 [%] F.S. | |||||||||

| DO (Dissolved oxygen) | ||||||||||||

| FL (O2flow rate) | ||||||||||||

| Rotational speed | DC0 - 10 [V] | |||||||||||

| Temperature sensor | DC1 - 5 [V] | |||||||||||

| MTA of outer surface | SUS304 (no coating), indoor type, non-waterproof, non-explosion proof specification | |||||||||||

| Installation | Indoor tabletop type | |||||||||||

| Outer dimensions/weight | W350×D400×H530 [mm] ・ Approx. 15 [kg] | |||||||||||

| Usage conditions | Temperature | 5 - 45 [℃] | Humidity | 20 - 85 [%] RH (No condensation) | ||||||||

| Sensors | Polarographic DO sensor/pH sensor manufactured by Mettler Toledo company | |||||||||||

| (Option: Optical DO sensor manufactured by Automatic System Research Co., Ltd.) | ||||||||||||

| Utilities | Power supply | AC100 [V], 50/60 [Hz], electrical outlet 2 gang (for main control unit and recorder) | ||||||||||

| N2 | Flow rate 50 [mL/min] or lower, supply pressure 0.2 [MPa], Connection port φ6 one touch tube fitting |

|||||||||||

| O2 | Flow rate 20 [mL/min] or lower, supply pressure 0.2 [MPa], connection port φ6 one touch tube fitting |

|||||||||||

| CO2 | Flow rate 50 [mL/min] or lower, supply pressure 0.2 [MPa], connection port φ6 one touch tube fitting |

|||||||||||

| AIR | Flow rate 150 [mL/min] or lower, supply pressure 0.2 [MPa], connection port φ6 one touch tube fitting |

|||||||||||

| *All of N₂, O₂, CO₂, and AIR must be dry and clean gases that do not contain corrosive components, dust, and oil mist. | ||||||||||||

| Item | Specifications | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Name | Culture controller | |||||||||||

| Model | S-BOX×10 Simple | |||||||||||

| Control | pH, DO (Dissolved oxygen) | |||||||||||

| Display range/accuracy | pH (Hydrogen ion concentration) | 0.00 - 14.00 [-] | Display accuracy: ±0.5 [%] F.S. | |||||||||

| DO (Dissolved oxygen) | 0.00 - 20.00 [mg/L] | |||||||||||

| Setting range | pH (Hydrogen ion concentration) | 0.00 - 14.00 [-] | ||||||||||

| DO (Dissolved oxygen) | 0.00 - 10.00 [mg/L] | |||||||||||

| Control type | pH (Hydrogen ion concentration) | ON/OFF control | ||||||||||

| DO (Dissolved oxygen) | ||||||||||||

| Data output | pH (Hydrogen ion concentration) | With data logger DC0 - 5 [V] |

Accuracy: ±0.5 [%] F.S. | |||||||||

| DO (Dissolved oxygen) | ||||||||||||

| Rotational speed | DC0 - 10 [V] | |||||||||||

| Temperature sensor | DC1 - 5 [V] | |||||||||||

| MTA of outer surface | SUS304 (no coating), indoor type, non-waterproof, non-explosion proof specification | |||||||||||

| Installation | Indoor tabletop type | |||||||||||

| Outer dimensions/weight | W260×D300×H350 [mm] ・ Approx. 12 [kg] | |||||||||||

| Usage conditions | Temperature | 5 - 45 [℃] | Humidity | 20 - 85 [%] RH (No condensation) | ||||||||

| Sensors | Optical DO sensor manufactured by Automatic System Research Co., Ltd. + pH sensor manufactured by Mettler Toledo company |

|||||||||||

| Utilities | Power supply | AC100[V], 50/60 [Hz], electrical outlet 2 gang (for main control unit and recorder) | ||||||||||

| O2 | Flow rate 20 [mL/min] or lower, supply pressure 0.2 [MPa], connection port φ6 one touch tube fitting |

|||||||||||

| CO2 | Flow rate 50 [mL/min] or lower, supply pressure 0.2 [MPa], connection port φ6 one touch tube fitting |

|||||||||||

| AIR | Flow rate 150 [mL/min] or lower, supply pressure 0.2 [MPa], connection port φ6 one touch tube fitting |

|||||||||||

| *All of O₂, CO₂, and AIR must be dry and clean gases that do not contain corrosive components, dust, and oil mist. | ||||||||||||